More Chair Joinery

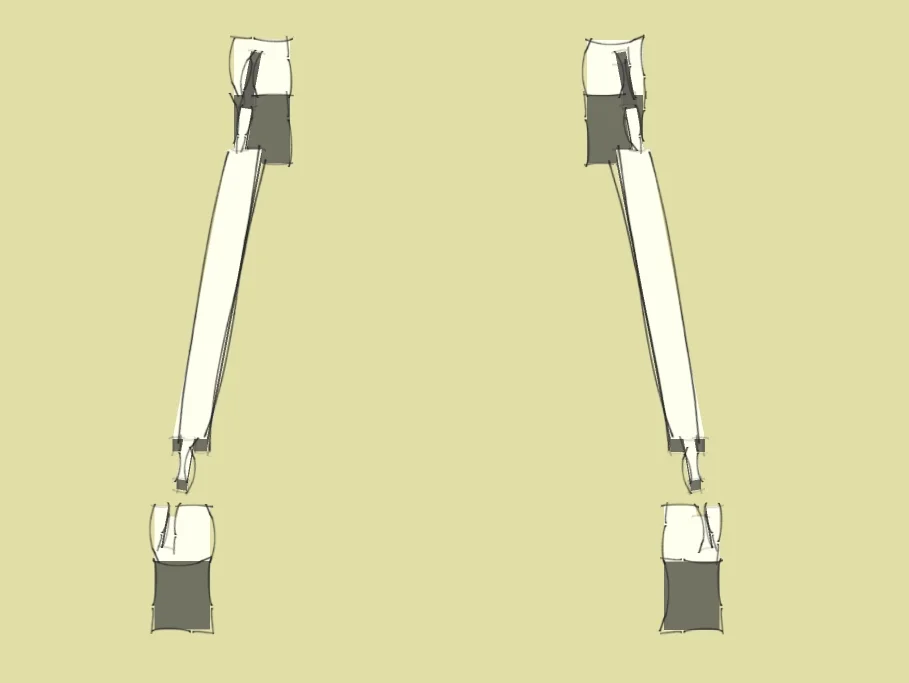

Angled Mortise and Tenon Joinery (sort of a cross section)

Harder to do by machine, although easier to do by hand is the angled mortise. The hard part of this joint is that the shoulders of the tenon are angled so they seat against the chair’s leg. The tenons are cut straight, just as for a normal, right-angled tenon. The mortise is cut at an angle. There are a couple of advantages to this. First, you don’t wind up with short grain on your tenons, as you might with a steeply angled tenon. The second advantage is less obvious, though no less important. With the mortises cut at an angle, the direction of the joint failure is not the same as the force that the joint sees; it’s at an angle. In other words, the chair back wants to move straight back under stress, but the joints don’t point straight back, and, in fact, point in two different directions. The same is true for the front of the chair. This makes it somewhat harder (although certainly not impossible) for the joint to fail.

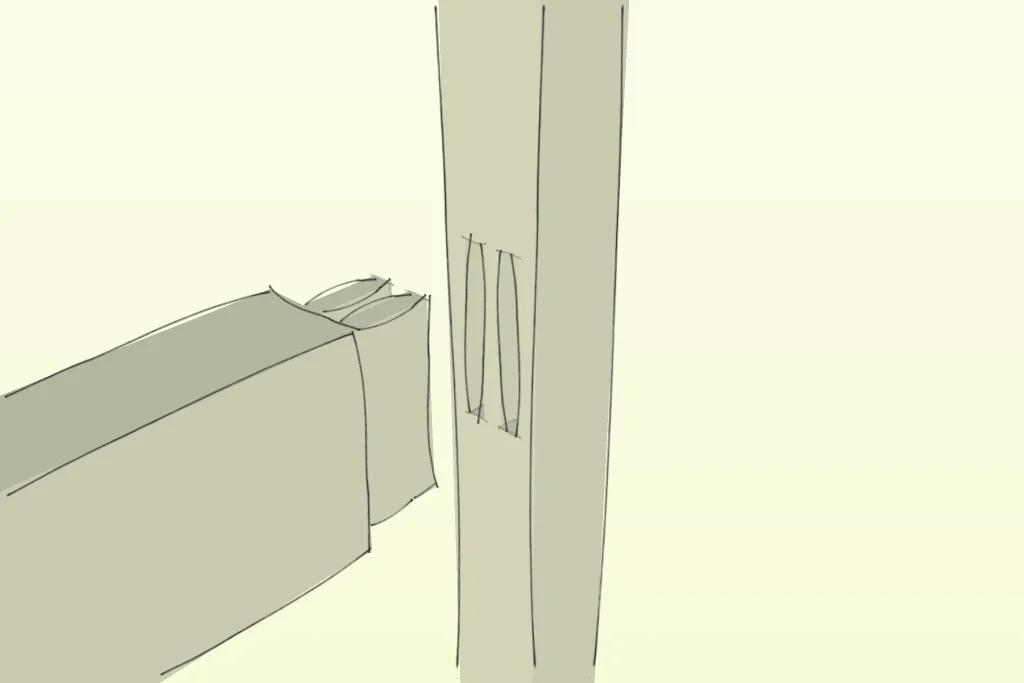

The twin mortise and tenon joint

There’s also the twin tenon, with twice the surface area of a regular tenon. There’s not often room for this joint, but when there is, it can be a very solid choice.